Tanks & Vessels

Plastic and GRP Fabrication for Chemical and Industrial Duty

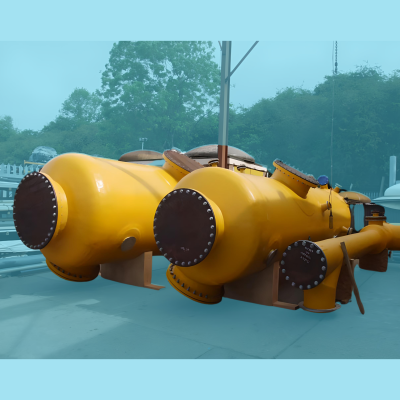

ERG Hygrade specialises in the fabrication of corrosion-resistant tanks, vessels and supporting equipment, manufactured in high-integrity thermoplastics and GRP.

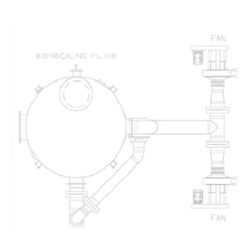

Our in-house team designs and builds chemical storage tanks, BS EN 13121-3 -compliant pressure vessels, reactor vessels, glove boxes, and dissolving tanks — all engineered to meet the chemical, thermal and structural demands of the application.

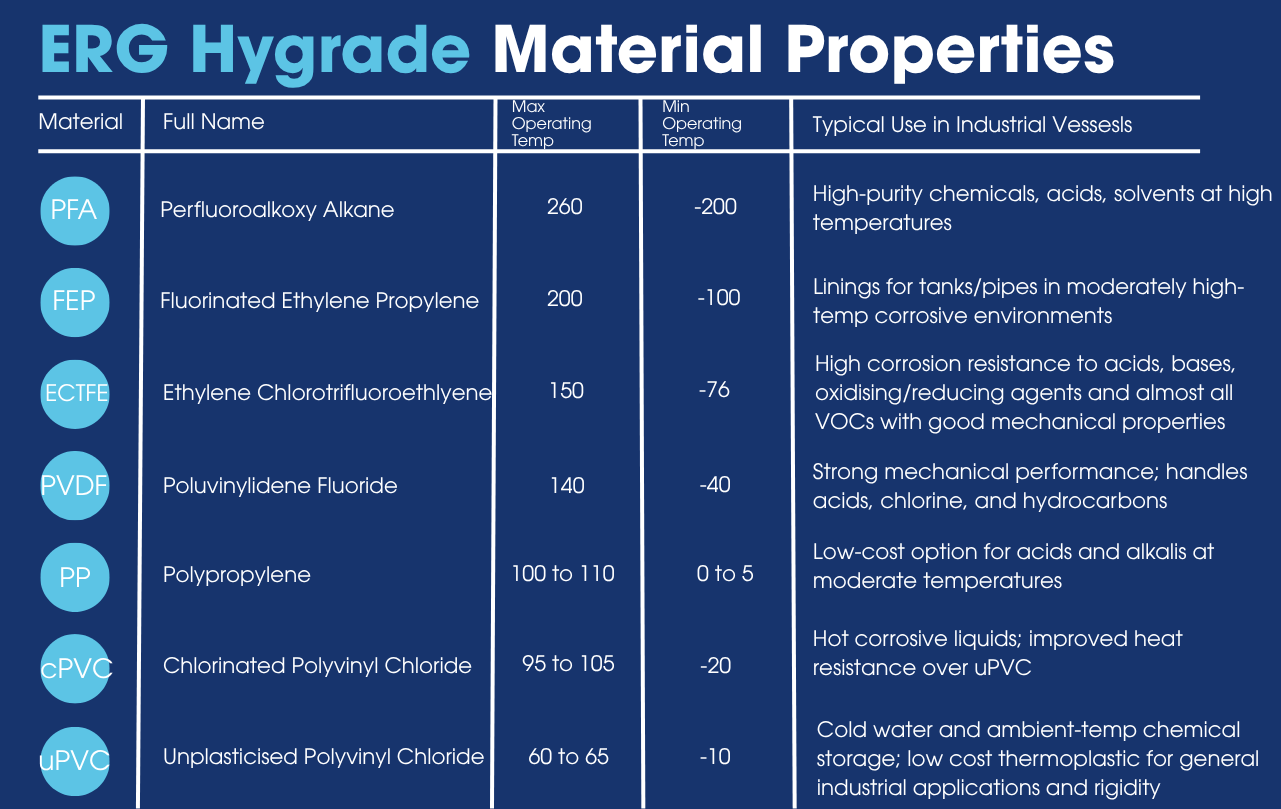

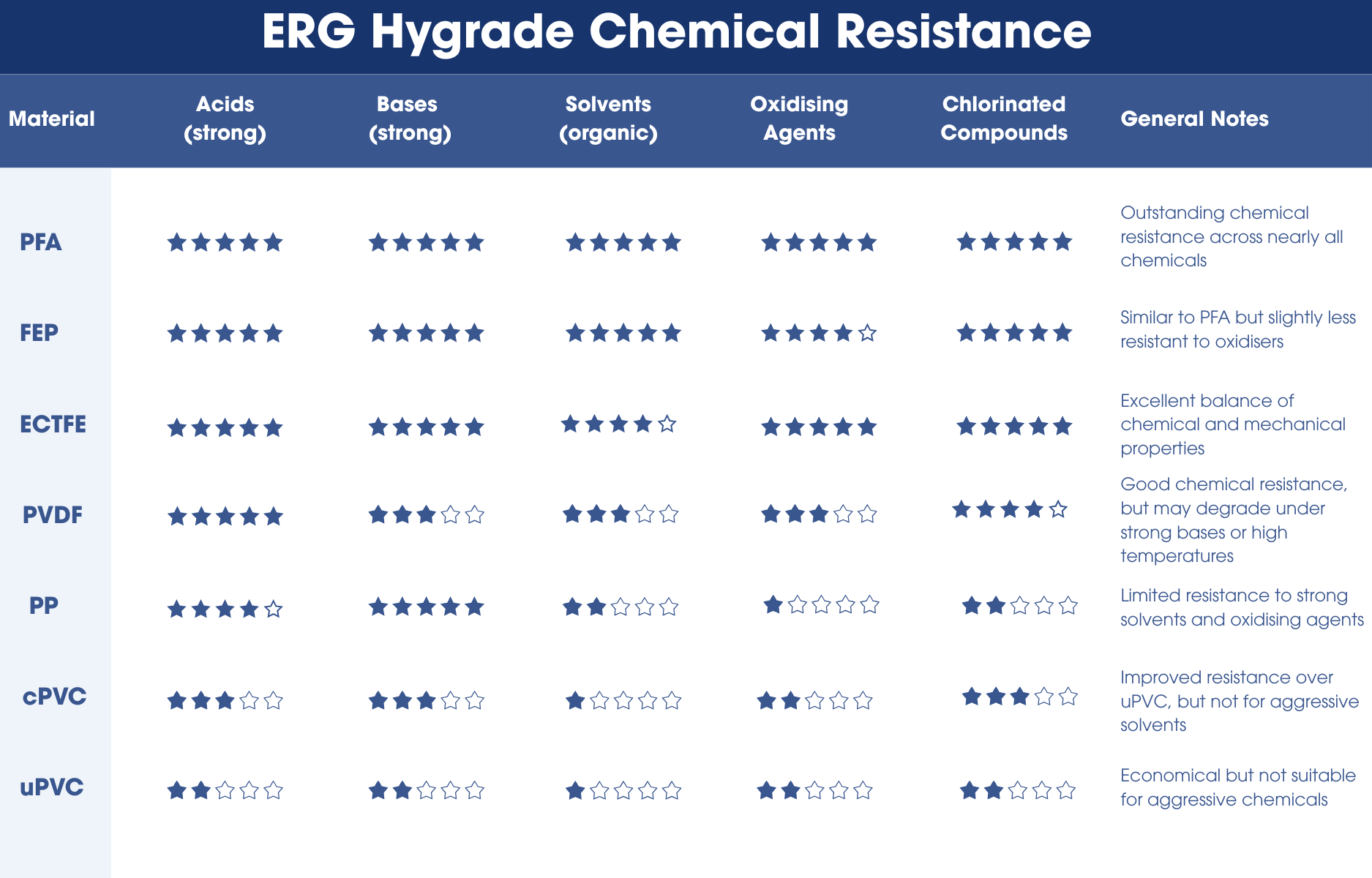

Materials offered: uPVC, PP, PVDF, ECTFE, FEP and PFA – all externally reinforced. (full table of materials shown below)

To support these installations, we also offer custom steelwork including structural frames, access ladders and platforms, ensuring a complete, integrated package that’s built to last.

Testing & Compliance

BS EN 13121-3 Standards and Inspection-Grade QA

Where required, ERG Hygrade provides laminate testing and certification in full compliance with BS EN 13121-3:2016.

Testing options include weld efficiency, peel strength and shear strength, with full inspection records and QA documentation available to support regulatory and project requirements.

Our commitment to quality and compliance ensures that all fabricated equipment not only performs in service but meets the highest industry standards for safety and reliability.

MATERIAL SELECTION

ERG Hygrade’s tanks, vessels & systems optimise the material selection to offer the right combination of heat and chemical resistance, longevity, robustness and price.