Two Systems, One Solution –

Dual-System Package for

High-Integrity Gas and Effluent Treatment

When a long-standing client unexpectedly lost access to shared gas scrubbing and effluent treatment infrastructure at a neighbouring plant, ERG Hygrade was commissioned to rapidly deliver a complete, self-contained replacement system — fabricated entirely in-house and tailored to the client’s specific process needs.

The project comprised two distinct but interrelated equipment packages:

-

A two-stage vertical packed tower scrubber system for removing highly concentrated chlorine gas (Cl₂) from air streams prior to atmospheric discharge

-

A Hydecat™ reactor unit to safely treat and neutralise sodium hypochlorite (NaOCl) effluent arising from scrubber blowdown

Both systems were precision-built using corrosion-resistant plastic materials, with supporting pipework, instrumentation and auxiliaries also supplied by ERG Hygrade as part of a full turnkey fabrication package.

The build quality from ERG Hygrade was excellent. Everything was delivered on time, exactly to spec, and has worked flawlessly since day one.

— Engineering Manager, Chemical Sector

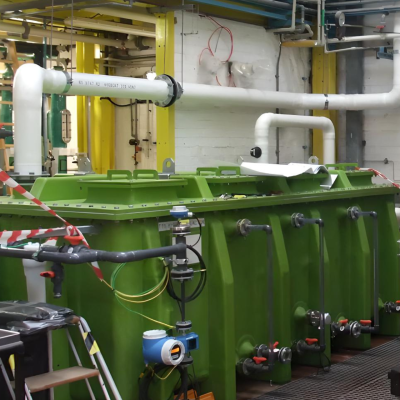

Hydecat™ Reactor for NaOCI Blowdown Treatment

To address the safe handling of spent Sodium Hypochlorite (NaOCl) blowdown, ERG Hygrade fabricated and installed a Hydecat™ reactor — a proprietary contact unit designed for high-efficiency hypochlorite destruction.

-

Designed for >56,000 ppm NaOCl inflow

-

Achieved >99.99% destruction efficiency, reducing output to <9 ppm before drainage

-

Fabricated for long service life and low maintenance